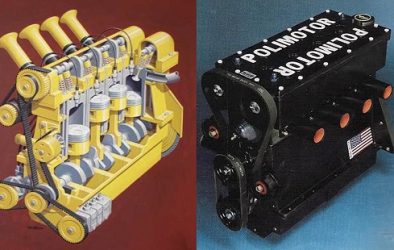

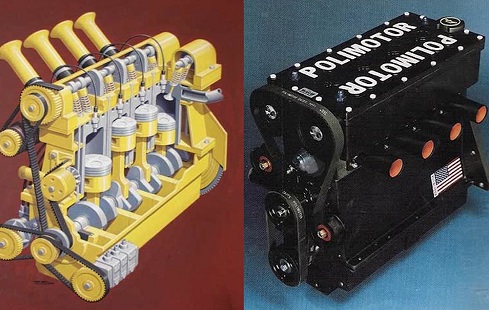

Solvay a chemistry company known for modern innovation for 153 years is a key sponsor for the Polimotor 2 project: an initiative to build an “all-plastic” engine that reduces overall engine weight by up to 30%. How is it possible to take 30% of the weight of an engine block off? Whaaaa?? But, that’s just what they did! The engine cylinder sleeves are metal; but the block is a tough, resilient thermoset plastic. Whaaaa?

Talking about 30%, Solvay projects a 30% increase in overall engine efficiency too! Whaaaa? Because of this efficiency, Plastics-Car.com sees this engine as contributing to the future of global automotive clean air initiatives. To make their point Solvay built that plastic engine for a racecar: Polimotor 1, as you saw on www.plastics-car.com starting back in the 1980’s.

Lightweighting & More

The focus for this second, newer edition racecar engine is, of course, morelightweighting and more efficiency; so it should also demonstrate CO2 reductions and increased energy conservation. Skilled polymer engineers use plastic thermoset [1] materials for high temperature resistance. They used a form of this plastic for the block, cam covers, oil pump, fuel lines, and throttle body of the engine. They create prototypes in 3D printed plastic then manufacture the real thing. According to Solvay, they are developing an all-plastic powertrain too. You heard it here, first.

How is a Plastic Automotive Engine More Efficient?

Think of it this way. The combustion engine is inefficient when cold. And, auto engines are usually cold when starting. That’s easy. Compare today’s outdoor temp to operating temperatures around 200 degrees F. “It’s still the same old story…” until a gas fueled combustion engine reaches that operating temperature (the first many miles), autos are notoriously fuel inefficient [2]. In fact, according to Tielong Shen “almost all of the harmful tailpipe exhaust gases are emitted during the short period after starting the engine,” (Transient Control of Gasoline Engines, 2015).

Polymers are a different material, they absorb and retain heat more than metal; metal transmits heat and throws it off. This energy absorption of plastics brings the engine to operating temperature quicker (read: more efficiently). Why doesn’t the plastic melt? First, the engine is a thermoset, not a thermoplastic material. Plus, appropriate internal cooling element passageways cool the engine, to govern the heat and prevent overheating.

Plastic Car Parts Have Come A Long Way

Brian Stern, the Global Ultra-Polymers Market Manager at Solvay Advanced Polymers, explained in an interview — Carbon fiber and glass fiber thermoset materials used in 1985 for the Polimotor 1 racecar engine. “Now” he says, “we use new, further evolved, lightweight “specialty polymers”. The science of thermoset materials now, as opposed to 30 years ago, will help bring this development closer to commercialization and mass production.

What’s a specialty polymer? Let an Expert Explain.

Solvay maintains strong roots in innovation by developing specialty polymers, such as the PEEK polymer that is used in the Polimotor 2 and on the Solar Impulse, a lightweight, solar powered aircraft. PEEK is a specific kind of thermoset material. Its qualities make it a common choice when phasing out metal in even the toughest areas in automotive, for instance, gearing. Next up? Transmissions. Here’s an expert’s opinion.

Bringing Plastic Engines into the Mainstream

The plastic industry and Solvay’s contribution to the all-plastic engine can save roughly 20 lbs in each vehicle for that component alone, while conserving energy at startup by using materials that better control the combustion “energy dissipation” process of the engine ー using the generated heat more efficiently than a standard metal engine. As we continue to see more success with thermoset materials, we take bigger steps towards major commercial applications of plastics in cars – not only side panels, the up-front crumple-zone, the chassis, wheels, the hoods, truck lids, roofs and now the engine. Looks like plastics are on the way.

Source: https://plastics-car.com/Blog/You-Wont-Believe-This-A-REAL-Plastic-Engine.html