polympart : Life-cycle assessment of polyurethane footwear application shows cold-curing technology is 89% more energy efficient than thermal curing.

Mar 08, 2023

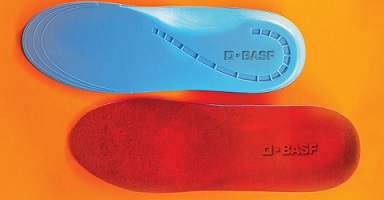

At this year’s Chinaplas in Shenzhen scheduled for April 17 to 20, materials supplier BASF will showcase a shoe component made with Elastopan polyurethane (PU) using cold-curing technology. According to a life-cycle assessment (LCA) of the shoe part by independent agency Intertek, cold-curing technology significantly reduced greenhouse gas emissions, water consumption, and energy use during production compared with conventional thermal curing.

“Compared to thermal curing, cold-curing technology was 89% more energy efficient as it does not require heat for the foaming process. Water consumption during the production process was 81% less than thermal curing. Greenhouse gas emissions were also down by 76%,” said Yunlong Ma, general manager of the Green Initiatives Department at Intertek.

Furthermore, cold-curing technology does not require the use of mold release agents. It also enables production at room temperature. As the heating process is eliminated, the production process is also simplified.

“With the LCA study, BASF is demonstrating that applications made with its Elastopan cold-curing solution is making a difference in contributing to a more sustainable future,” said BASF’s Andy Postlethwaite, senior vice president of Performance Materials Asia Pacific. “It is also part of BASF’s continuous efforts to excite footwear customers with innovative solutions that give them a clean win in the market race for more sustainable footwear.”

BASF’s PU solution based on cold-curing technology has already been used in shoe parts by leading footwear manufacturers. Details of the LCA study and Elastopan cold-curing technology will be provided during a tech talk at Chinaplas 2023 on April 18.

BASF will exhibit in hall 17 in booth 17F.

Source: www.plasticstoday.com

مریم مهاجر