Fine powders and granular materials are extensively used in industrial applications. It is essential to precisely characterize these materials in order to control and optimize processing techniques. The characterization techniques are related to the properties of the grains (morphology, granulometry, chemical composition, etc.) or to the behavior of the bulk powder (density, flowability, electrostatic properties, blend stability, etc.).

However, when it comes to characterizing the physical behavior of bulk powder, a majority of the methods used in quality control or R&D laboratories are based on outdated measurement methods. In the past 10 years, these methods have been updated by Granutools to satisfy the current demands of production departments and R&D laboratories. Specifically, automation of the measurement processes has been performed and stringent initialization techniques have been created to achieve interpretable and reproducible results. Furthermore, the precision of the measurements can be improved by using image analysis techniques.

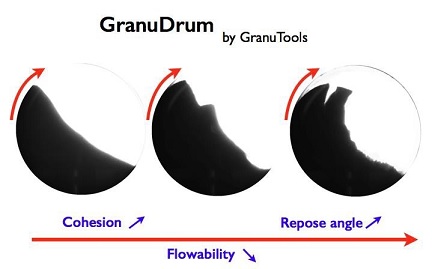

A wide array of measurement techniques has been devised to fulfill all the demands of industries that process granular materials and powders. However, the focus of this article will be on the GranuDrum, GranuPack, and GranuCharge instruments.

Download Full text : https://polympart.com/wp-content/uploads/2019/03/Aging-Characterization-of-Polymer-Powders-in-Additive-Manufacturing.pdf

Source: https://www.azom.com/article.aspx?ArticleID=17651