Stress-induced acid formation shows location and timing of damage

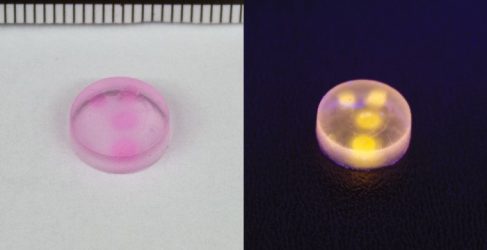

Applying pressure to this polymer disk caused acid to be released from the polymer, turning the pH indicator rhodamine B pink within the disk (left). Rhodamine B appears fluorescent yellow under UV light (right).

Apolymer that releases acid in response to a hammer blow can trigger “bruising” that reveals where and when it was struck (J. Am. Chem. Soc. 2020, DOI: 10.1021/jacs.9b12861). This kind of mechanochemistry—in which a mechanical force sets off a chemical reaction—could eventually lead to materials that offer an early warning signal of impending structural failure, for example. “The overall goal here is to create useful stress-responsive materials,” says Stephen L. Craig of Duke University, whose PhD student Yangju Lin led the work.

Polymer mechanochemistry relies on chemical groups called mechanophores, which undergo a chemical change when they are stretched or compressed. Craig’s team developed a new mechanophore called 2-methoxy-substituted gem-di-chlorocyclopropane (MeO-gDCC). The researchers incorporated repeating units of MeO-gDCC into polymer chains and then blasted the resulting molecules with ultrasound. This blast breaks a carbon-carbon bond in the cyclopropane ring to generate an allyl chloride intermediate, which can rearrange to release hydrogen chloride. Given the number of MeO-gDCC units in each polymer molecule, every chain produces an average of 67 protons in this way.

A polymer containing the mechanophore 2-methoxy-substituted gem-di-chlorocyclopropane releases acid under mechanical stress.

Previous mechanoacids have suffered from limited thermal stability or were only able to release a single proton from each polymer chain, drawbacks that MeO-gDCC overcomes. “This chemistry addresses all the shortcomings of the prior acid-generating mechanophores,” says Jeffrey S. Moore of the University of Illinois at Urbana−Champaign, who developed one of the few other mechanoacid polymers. “It’s a very exciting advance.”

Craig’s team also studied the mechanoacid with single-molecule force spectroscopy, a technique that involves stretching a single polymer chain with an atomic force microscope.

The researchers used this technique to compare their mechanoacid polymer with an equivalent polymer whose mechanophores lacked a methoxy substituent. Under a force of 880 pN, the methoxy-substituted mechanophores popped open about 1 million times as fast, meaning they were much more responsive to stress. The researchers attribute this to the methoxy group stabilizing the mechanophore’s transition state during ring opening. “Just a simple change of design, adding the methoxy, can lead to these new properties,” says Guillaume De Bo of the University of Manchester, who also works on polymer mechanochemistry.

Single-molecule experiments are a long way from real-world applications, though. So the researchers created a 6 mm wide polymer disk by blending their mechanoacid with poly(dimethylsiloxane) and the dye rhodamine B, which turns pink when protonated. When they hit the disk with a hammer, the polymer released acid that slowly spread through the material and reacted with the dye to create a pink bruise. The researchers could estimate when the blow was struck by measuring the extent of the color change, and they were accurate to within a few minutes for periods up to half an hour. It marks the first example of a mechanoacid being used in a bulk material, the team says.

Craig suggests that the ability to time-stamp a mechanical shock in this way could prove useful in pinpointing the particular event that led to the failure of a mechanical part, in areas as diverse as medical devices or remotely operated drones. The protons released by the mechanophore could also be harnessed to trigger self-repair reactions in a damaged polymer, adds De Bo. “It’s simple enough that it could eventually be applied in real systems,” he says.

Source: https://cen.acs.org/materials/polymers/Mechanoacid-polymer-signals-smash-hit/98/web/2020/01