BERGAMO, Italy, Dec. 13, 2019 — Graphene Flagship partners developed a graphene-titania composite via a one-step procedure to widen and improve the applicability of “smog-eating” cement. The prepared composite showed enhanced photocatalytic activity, degrading up to 40% more pollutants than pristine titania in the model study, and up to 70% more pollutants in the case of nitrogen oxides (NOx). Organic pollutants, such as (NOx) and volatile compounds, are emitted mostly by vehicle exhausts and industry and are the primary cause of air pollution, the researchers said.

The Graphene Flagship team working on photocatalytic coatings, coordinated by Italcementi, HeidelbergCement Group, Italy, developed the composite material. It performed liquid-phase exfoliation of graphite in the presence of titania nanoparticles at atmospheric pressure and in water, without heating or adding any surfactant, and using low-cost commercial reagents, to create the graphene-titania nanocomposite.

To understand the photo-physical mechanisms underlying the enhanced performance of the composite material, the researchers used ultrafast transient absorption spectroscopy to investigate the photo-generation of reactive species (trapped holes and electrons). They observed an electron transfer process from titania to the graphite flakes within the first picoseconds of the relaxation dynamics, which caused the charge recombination rate to decrease and the efficiency of the reactive species photo-production to increase.

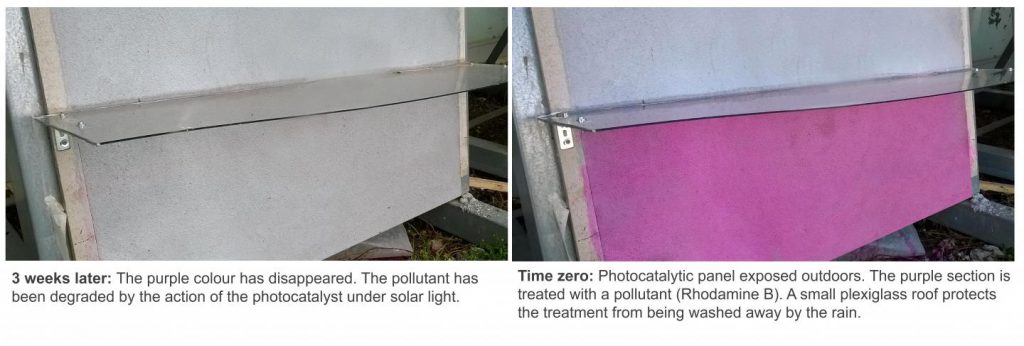

The photocatalyst degrades up to 70% more atmospheric nitrogen oxides than standard titania nanoparticles in tests on real pollutants. Courtesy of Italcementi/Heidelberg Cement/Graphene Flagship.

The researchers used rhodamine B as a model for volatile organic pollutants because its molecular structure closely resembles those of pollutants emitted by vehicles, industry, and agriculture. They found that 40% more rhodamine B was degraded by the graphene-titania composite than by titania alone, in water under UV irradiation. “Coupling graphene to titania gave us excellent results in powder form — and it could be applied to different materials, of which concrete is a good example for the widespread use, helping us to achieve a healthier environment,” researcher Marco Goisis said. “It is low-maintenance and environmentally friendly, as it just requires the sun’s energy and no other input.”

The graphene-titania composite could be coated on the surface of materials to passively remove pollutants from the air. If the coating was applied to concrete on the street or on the walls of buildings, the harmless photodegradation products could be washed away by rain or wind or manually removed.

Xinliang Feng, Graphene Flagship work package leader for functional foams and coatings, said, “Photocatalysis in a cementitious matrix, applied to buildings, could have a large effect to decrease air pollution by reducing NOx and enabling self-cleaning of the surfaces — the so-called smog-eating effect. Graphene could help to improve the photocatalytic behavior of catalysts like titania and enhance the mechanical properties of cement.”

There are challenges to be addressed before the composite material can be used on a commercial scale. Cheaper methods to mass-produce graphene are needed, the researchers said. Interactions between the catalyst and the host material need to be expanded, as well as studies into the long-term stability of the photocatalyst in the outdoor environment.

The research was published in Nanoscale (doi:10.1039/C9NR06760D).

Source: https://www.photonics.com/Articles/Graphene_Composite_Improves_Photocatalytic/a65375