PolymPart: Researchers at Fraunhofer Umsicht (Fraunhofer institute for environmental, safety and energy technology) have developed a ‘bipolar plate’ (explained below) for bipolar construction batteries (ditto) that is flexible and can be made on a roll-to-roll process.

“We manufacture bipolar plates from polymers that have been made electrically conductive,” said Fraunhofer researcher Dr Anna Grevé. “In this way, we can produce very thin plates and, compared with conventional cells connected by wires, save over 80% of the material used.”

In addition, the material does not corrode, it can be shaped – for example, embossed to create fluid channels for fuel cells or flow batteries – and it can be sealed to the battery housing by welding. ”

“Conventional bipolar plates, are unsuitable for welding due to the thermal and mechanical stressing of the material during manufacture,” according to the Fraunhofer. “Joining them in such a way that neither gases nor liquids can pass through the joints requires seals, however seals become quickly porous, and they also take up space.”

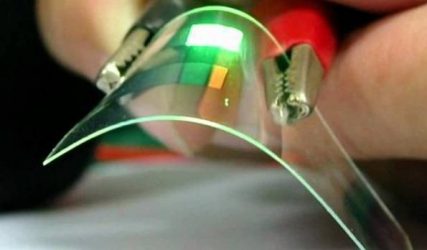

And varying the composition allows flexibility to be tuned from “so flexible that you can wrap them around your finger” to completely stiff said Grevé.

Mixture of conductive polymer and graphites

The material is a mixture of ~80% conductive polymer and ~20% graphites. “We use commercially available polymers and graphites, but the secret is in the recipe,” said Grevé. “The processing methods have little in common with ordinary polymer processing.”

Mixing and manufacture of the plates is achieved in a roll-to-roll process. “We were able to fulfil all requirements in one process. Consequently, the plates can be used just as they are when they come out of the machine,” said Grevé.

The project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi).

At the Hannover Messe from April 1 to 5, 2019, Grevé and her team will be show a 3.2m2 bipolar plate intended for large-scale redox flow batteries (hall 2, stand C22).

Bipolar plate? Bipolar battery?

The term ‘bipolar’ when applied to batteries has got nothing to do with electro-chemistry, nor the polarity of terminals.

Instead it refers to a form of mechanical construction that shrinks battery size and reduces internal resistance by changing the way cells within a battery are connected together.

For example, internally, conventional car batteries consist of six pockets into which are built six 2V pb-acid cells. To pass current from one cell to the next, Pb-alloy straps run across the tops of the pockets from one cell to the next. And within each cell vertical conductors are included to pass current up to the top straps.

This-strap-and-vertical-conductor inter-cell connection technique has been (apparently retrospectively) dubbed ‘monopolar’ contruction.

Bipolar construction replaces the walls between cells with a conductive plate – ‘bipolar plate’ – sealed into the housing.

Immediately this brings the height of the battery down, cuts weight and, given the right bipolar sheet material, can reduce series resistance.

However, bipolar construction removes the inherent simplicity of electrically-isolated moulded plastic pockets.

Firstly, some amount of force now has to be provided right through the battery to squash the various layers together to maintain all the electrical connections.

Then the sealing around the edge of the bipolar plate – which keeps the electrolyte from one cell from electrically shorting to the electrolyte in the next cell – has to flex enough to allow that force to pass along, while still lasting the life of the battery.

Thirdly, the bipolar plate must take no part in the electro-chemistry of the cell, otherwise it will corrode, and could set-up a potential that opposes the battery output.

This last point largely precludes the use metal bipolar plates and brings conductive ceramics and carbon-loaded polymers to the fore.

Source: https://www.electronicsweekly.com/news/research-news/conductive-polymer-sheet-shrink-car-grid-storage-batteries-2019-01/